Satellites’ Assembly, Integration and Test (AIT)

ALTEN capitalises on more than20 yearsof know-how inpreparations for the assembly,validation testsandfinal integration(之前劳恩ch) of various satellites forCNES and other industrial customers.

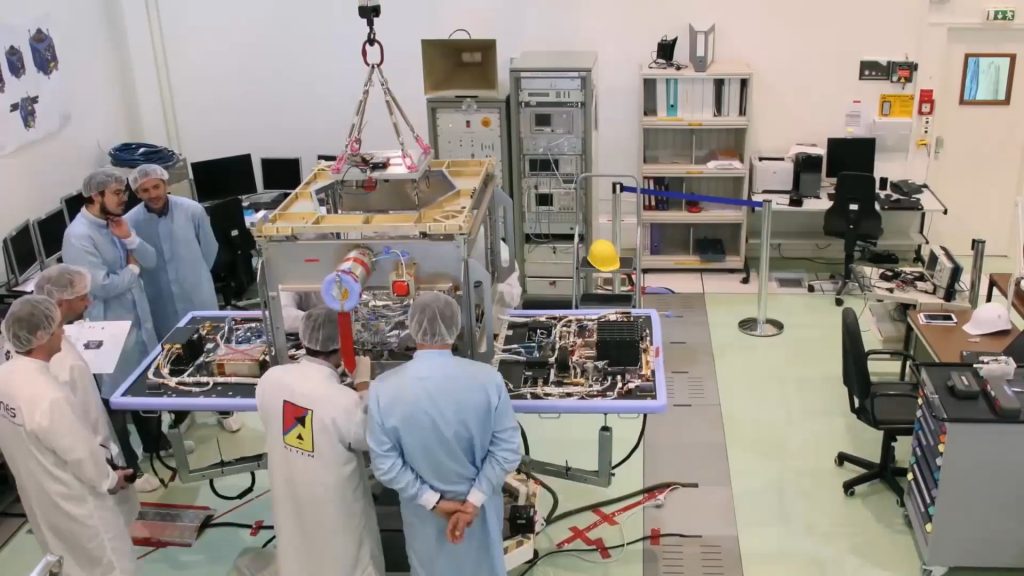

Satellites contain extremely costly electronic equipment (sometimes in excess of1 million euros) with lengthy manufacturing times. Integrating these sub-systems on the satellite platform requires精度andpreparation. By relying onmulti-disciplinary teams of engineers(space systems architecture, electricity/electronics, real-time systems, radio frequency, optical engineering, mechanical engineering, thermal engineering, etc.), ALTEN’s responsibility is to:

- Prepare the satellite’s integration: define the integration procedures for operators

- Check that sub-systems are operational (power supply, radio communications, onboard management, orbit or altitude control, optical instruments, mechanical structure, etc.)

- Check that the satellite is operational after assembly (environmental trials in space or launch conditions: extreme temperatures, near-vacuum pressure, vibrations and electromagnetic compatibility).

ALTEN’s engineers work in cleanroom (ISO8 & ISO5 classes) as well as on launch sites (Kourou, Baikonur, Jiuquan, etc.), on different types of satellite projects in a variety of fields:research(such as TARANIS, the study of transient luminous events – TLE – and terrestrial gamma-ray flashes),Franco-Chinese cooperation(CFOSAT, the study of wind and waves on the ocean surface) and theconstellation of 600 telecommunications mini-satellites(ONEWEB)。